www.separationdesign.com

Magnetic Particle Tracking System

The Magnetic Particle Tracking System or MPTS is a unique inexpensive way to measure the detailed dynamics of solids flows in a variety of systems. It can readily obtain the detailed data to understand and improve complex multi-phase (gas-solids, liquid-solid or bulk solid) flow systems. Unlike other methods such as MRI, PET, CAT or radioactive particle tracking, the MPTS is relatively inexpensive and easily implemented without the need of highly trained specialists or dangerous materials or energy fields.

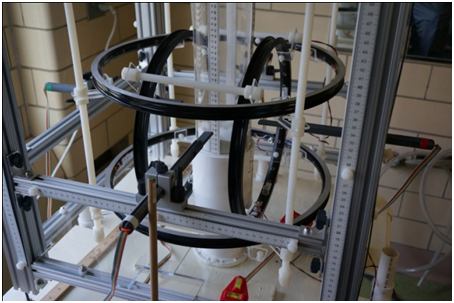

It is based on passively monitoring magnetic fields from neodymium magnets imbedded in tracer particles with an array of highly sensitive and specially calibrated magnetic field sensors arranged in a way to optimize the quality of the data needed in a particular application.

Currently we are beta testing a third generation system which has markedly improved sensitivity and versatility over our original system.

How it Works:

The basic principle behind this tracking method is that the measured field strength at each of four or more probes is a function of the distance between the tracer and the probe tip and simultaneous measurements by the multiple probes will allow the position of the tracer to be calculated.

An obvious difficulty in interpreting such probe signals is the vector nature of the tracer’s magnetic field. If the tracer were randomly reoriented by fluid or solids turbulence, accurately determining tracer position from a few probe signals would be extremely difficult. However, contrary to this intuition, we found that the tracer particle tends to align its magnetic axis with the earth’s magnetic field (like a compass needle). It does so along the earth’s magnetic field lines including the declination at a particular location. We can control and enhance this tendency by superimposing generated magnetic fields on the testing volume. By carefully calibrating tracer-sensor combinations and using proprietary algorithms, we are able to convert multiple (four or more) time series magnetic field data into XYZ position data for the tracer and accurately map the trajectories of the tracer in the flow system.

Applications:

We have used this system to perform studies of solids flows in both spouted and bubbling fluidized beds for applications in pyrolysis of biomass and dense particle processing. These studies in conjunction with Oak Ridge National Laboratory have yielded valuable new insights into emerging green energy technology systems and provided validation data for computer modeling studies to evaluate and scale up these systems.

Other applications for MPTS are obvious. Other fluidized systems including entrained flow systems, studies of solids residence time distribution in both gaseous and liquid systems, solid-liquid flowing systems including mixing, bulk solids flows such as in hopper and bins, or vibratory, segregation or compaction tests in solids handling systems. In fact in any system where detailed motion of solids is needed is a potential application for MPTS.

Limitations:

Because we use magnetic fields to monitor particle motion, the system must maintain and transmit these fields to external sensors. This limits the temperature to below the Curie temperature of the magnetic material used and the vessel and or components must not be ferromagnetic but may be constructed of materials such as aluminum, acrylic, glass, nylon, stainless or other materials. MPTS has been used in vessel sizes up to 4 inches diameter and as deep as desired. Larger vessel diameters are possible with some development.

More Information

Publications with generation 1 and 2 systems see:

Patterson, E.E.; Halow, J.; Daw, C.S. An Innovative method using magnetic particle tracking to measure solids circulation in a spouted fluidized bed. Ind. Eng. Chem. Res. 2010, 49, 5037-5043.

Halow, J.; Holsopple, K.; Crawshaw, B.; Daw, Observed Mixing Behavior of Single Particles in a Bubbling Fluidized Bed of Higher-Density Particles. Ind. Eng. Chem. Res., 2012, 51, 14566-14576.

Interested?

Contact Dr. Jack Halow at Separation Design Group-

931 Rolling Meadows Rd

Waynesburg, PA 15370

(724) 852-1035

sdgroup@separationdesign.com

We would be happy to discuss sponsored studies of your system or quoting an instrument for you lab to meet your multiphase dynamics research needs.

![]()